Magnetic Characteristics Test

Importance of the quality of electromagnetic steel sheets.

In recent years, there has been a strong demand for electrical equipment with high performance and low power consumption from the perspective of environmental protection and CO2 reduction.

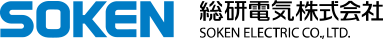

Electrical equipment such as rotators, generators and transformers is mainly composed of three materials: copper (winding), iron (magnetic circuit), and insulation, and these three materials have a significant impact on the quality of electrical equipment.

In particular, electromagnetic steel sheets (silicon steel sheets) which make up magnetic circuits play an extremely important role in the manufacture of stable and efficient energy-saving products.

<Fig.1 Losses in rotating machines>

<Fig.1 Losses in rotating machines>

Single Strip Test

The type and grade of electromagnetic steel sheets are determined by their magnetic properties.

Generally, steel makers perform magnetic property tests with an Epstein measurement.

The Epstein measurement is a test method that has long been used in commercial transactions worldwide because it provides reproducible values in a particular test condition.

However, conducting the Epstein measurement requires the expertise and time to cut electrical steel sheets in the correct direction and size using an appropriate cutting tools and to set 12 or more samples into an Epstein frame.

To meet the demands for easy confirmation of the grade of electrical steel sheets, SOKEN has developed a single sheet tester that can easily determine the overall iron loss value with only a single sheet. It was developed as DAC-IR-1 at the time of SOKEN establishment in 1975, and is now updated to Model DAC-IR-3.

<DAC-IR-3>

<DAC-IR-3>

DAC-IR-3 has a built-in U-shaped yoke integrated into the measuring probe.

An exciting coil and a magnetic flux detection coil are wound around the U-shaped yoke, and the magnetic path is formed by placing the yoke on a steel sheet.

The core loss of the sample sheet is calculated from the current flowing through the exciting coil and the voltage generated in the magnetic flux detection coil.

With DAC-IR-3, you can easily check the iron loss value by setting the plate thickness and selecting the magnetic flux density from 1T, 1.5T or 1.7T.

DAC-IR-3 can easily determine the grade of the sample sheet that is closely coincident with data obtained by Epstein Method.

Analysis of electromagnetic steel sheets

<DAC-BHW-6>

<DAC-BHW-6>

With Model DAC-BHW-6, further analysis of electromagnetic steel sheets is possible.

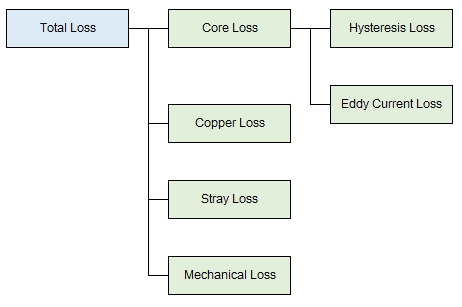

DAC-BHW-6 can perform testing with test frequency up to 400Hz, and enables to observe hysteresis loss and eddy current loss separately.

B-H Graph : B-H Characteristics (flux density vs. magnetizing force)

B-W Graph : B-W Characteristics (flux density vs. core loss)

W-F Graph : W-F Characteristics (iron loss vs. frequency)

μ-F Graph : µ-F Characteristics (permeability vs. frequency)

W Discrimination: Eddy current loss and Hysteresis loss are discriminated from Iron loss.

<Fig. 2 Discrimination Graph with DAC-BHW-6>

<Fig. 2 Discrimination Graph with DAC-BHW-6>

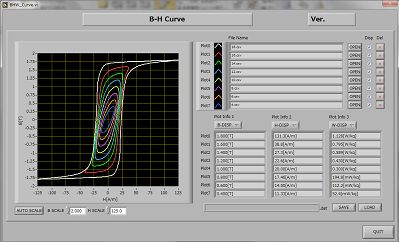

<Fig. 3 B-H Curve display>

<Fig. 3 B-H Curve display>

Stator Core Tester

DAC-LST-3 is designed to judge the quality of lamination stator cores used in small motors.

A PWM inverter method is introduced in the power supply for magnetizing the stator core. This realizes a compact design and supports the excitation power frequency up to 400Hz.

DAC-LST-3 makes a pass/fail judgment by comparing the value of the stator selected as a reference from among your stators.

Comparative measurement with DAC-LST-3 makes it possible to judge the quality of complex-shaped stator cores, where it is difficult to accurately determine the magnetic path length and cross-sectional area.

The values of magnetic flux density (B), magnetizing force (H) and iron loss (W) are compared with the standard values and judged respectively while increasing the magnetic flux density (in B mode) or magnetizing force (in H mode) to the target value.